Product outline

Features

F160 is a weighing controller ideal for the use in a limited space such as the inside of a control panel. In addition to a high-accuracy amplifier with extremely low drift installed, various high-specification functions such as high-speed sampling, and the weighing sequence function and control input-output which are convenient for automatic weighing machines, are packed into a compact body.

Compact size that can realize integration into a control panel

67 (W) × 185 (H) × 120 (D) mm

High-speed sampling & high display resolution

High-speed A/D conversion and powerful digital processing capability of 1000 times/sec..

High display resolution of 1/10,000 is assured for all input ranges. (Internally 1/40,000)

Super low drift

Zero drift of 0.1 μV/°C is realized by high-accuracy head amplifier for load cell. (Typical value [Typ]: 0.08 μV/°C)

Interface ideal for connection with PLC

Equipped with small display unit and setting keys

It is of compact design, but a display unit and setting keys are equipped to check indicated values and set the main unit.

(Setting from the host such as PLC is made possible by installing an optional interface.)

Weighing sequence function

Feeding and discharging gates can be directly controlled only by giving weighing instructions.

Higher-speed weighing and control system line, which is not affected by PLC command timing, can be constructed.

Substantial functions that support weighing

– Automatic free fall compensation: Actual free fall fluctuations that are one of the key factors of weighing errors are automatically compensated.

– Zero tracking: The slow zero drift and the zero point shift caused by temperature fluctuations are automatically compensated.

Characteristic selectable powerful filters

Bessel low-pass filter to eliminate mechanical vibrations and moving average-type filter to prevent weight value drift are equipped.

Vertically or horizontally mountable fittings

Detachable two-piece type terminal block

A space-saving, screw-type terminal block is adopted for the load cell connection section. The terminal block is of the two-piece type that allows its removal from the main unit.

Specifications

Analog section|Setting section|I/O section|Display section|General specifications|Attachments

| Analog section | |

| Excitation voltage | DC 10 V±5%, output current within 120 mA Remote sensing (Up to four 350 load cells can be connected in parallel.) |

|---|---|

| Zero adjustment range | 0 to approx. 2 mV/V (automatic adjustment by digital computation) |

| Gain adjustment range | 0.3 to 2.0 mV/V (automatic adjustment by digital computation) |

| Signal input range | 0.0 to 2.0 mV/V |

| Minimum input sensitivity | 0.3 μV/count |

| Accuracy |

Non-linearity: within 0.01% FS (Typ. 0.005%/FS Normal temperature) Zero drift: within 0.1 μV/℃ RTI (Typ. 0.08 μV/℃) Gain drift: within 15 ppm/℃ (Typ. 5 ppm/℃) |

| Analog filter | Bessel low-pass filter-12 dB/oct, cutoff frequency 2/ 4/ 6/ 8 Hz |

| A/D converter | Rate: 1000 times/sec. Resolution: 24 bit(binary) |

| Setting section | |

| Setting item | ● Final/ Set point 1/ Set point 2/ Compensation (CPS)/ Over/ Under/ Upper limit/ Lower limit/ Near zero/ Preset tare value ● Comparison inhibit time/ Judging time/ Complete output time/ Adjust feeding time/ Auto zero times/ Judging times/ Auto free fall compensation coefficient/ Average count of auto free fall compensation/ Auto free fall compensation regulation ● Over/Under comparison/ Upper/Lower limit comparison/ Near zero comparison/ Feed/discharge control mode/ Preset tare weight/ Auto free fall compensation/ Complete output mode/ Over/Under comparison mode/ Upper/Lower limit comparison mode/ Net weight sign inversion in discharge weighing ● Digital filter/ Motion detection (period)/ Motion detection (range)/ Zero tracking (period)/ Zero tracking (range)/ Analog filter/ Filter in a stable condition/ Motion detection mode/ Option setting (None, BCD, CC-Link)/ SI/F G/N selection ● Balance weight/ Capacity/ Minimum scale division/ Net over/ Gross over/ Digital zero regulation value/ Decimal place/ Gravitational acceleration/ Calibration value LOCK (SOFT LOCK)/ Set value LOCK (SOFT LOCK) ● Simple comparison/ Sequence mode selection/ Adjust feeding in sequence mode/ Near zero check in sequence mode/ Weight value check in sequence mode ● External control output selection 0/ External control output selection 1/ External control output selection 2/ External control output selection 3/ External control output selection 4/ External control output selection 5/ External control output selection 6 ● External control input selection 0/ External control input selection 1/ External control input selection 2/ External control input selection 3/ External control input selection 4 ● Tare subtraction/ Tare reset/ Digital zero/ Digital zero reset/ Sequence start/ Sequence stop/ Sequence error reset ● Zero calibration/ Actual load calibration/ Equivalent input calibration (rated output value)/ Password |

|---|---|

| I/O section | |

| External output signal (7) |

Each control output is selectable by setting. Near Zero, SP1, SP2, SP3, Under, Go, Over, Complete, Normally OFF, Lower Limit, Upper Limit, Stable, Weight Alarm, Sequence Error, Final Error, In Operation (RUN), Clock (in an approximately one-second cycles) Transistor open collector output (sink type)ON when the transistor is ON Vce = 30 V(Max), Ic = 50 mA(Max) |

|---|---|

| External Input signal (5) |

Each control input is selectable by setting. Digital Zero Reset, Digital Zero, Tare Subtraction, Tare Reset, HOLD or Judge, Feed/Discharge, Sequence Start, Sequence Stop, No Function ON when short-circuited with the COM terminal. (Dry contact type) |

| Interface | SIF: SI/F 2-wire serial interface (Standard) This is a simple output serial interface for connection of a UNIPULSE-manufactured printer, external display, etc.. BCO: BCD parallel data output interface (Option) Transmits weight data to a PLC or other BCD devices. CCL: CC-Link interface (Option) Serial bus interface for connection with PLC. |

| Display section | |

| Display unit | Character height 8 mm 7-segment red LED, 6 digits |

|---|---|

| Measured value | 5 digits: -99999 to +99999 |

| Decimal point | 0, 0.0, 0.00, 0.000 selective |

| Display frequency | 25 times/sec. (Speed of system 1000 times/sec.) |

| General specifications | |

| Power supply voltage | DC 24 V(15%) |

|---|---|

| Power consumption | 10 W(Max) |

| Operating conditions | Temperature: Operating temperature range -10℃ to +40℃ Storage temperature range -20℃ to +80℃ Humidity: 85% RH or less (non-condensing) |

| Dimensions | 67(W) × 185(H) × 120(D) mm (Not including projections) |

| Weight | Approx. 1.2 kg |

| Attachments | |

| Control signal Input/Output connector | 1 |

|---|---|

| Jumper wire | 2 |

| Wall anchor (It attached main body.) | 2 |

| Operation manual | 1 |

| Connector for BCD output (with BCD option) | 1 |

| Connector for CC-Link (with CC-Link option) | 1 |

Option

| Model | |

| BCO | BCD parallel data output interface |

|---|---|

| CCL | CC-Link interface |

| Number of option installations | 1 |

Optional accessories

| Model | |

| CN20 | 57 series 14p connector for external I/O |

|---|---|

| CN51 | BCD Output connector |

| CN71 | CC-Link connector |

| CN80 | Analog I/O connector terminal |

Please note that there are possibilities of individual differences in a color tone on display devices such as LEDs, fluorescent display tubes and LCDs due to manufacturing process or production lots.

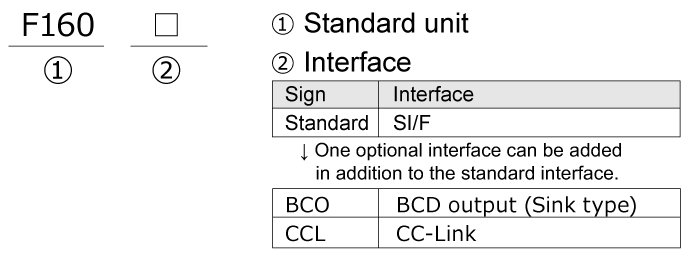

Structure of product code

Download

|

Product catalogue(PDF)

|

⇒Download Page | |

|---|---|---|

|

Operation manual(PDF)

|

||

|

External dimension

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||